Different bike helmet testing standards reflect regional safety regulations like for USA (CSPC), Europe (CE) and Australia (AS/NSZ) before helmets can legally be sold there. They also test for biking-specific scenarios that are different from motorcycle helmets.

That’s why there are so many and all reputable MTB helmet brands usually pass all the mandatory ones, and often more rigorous voluntary ones as well.

Key Takeaways

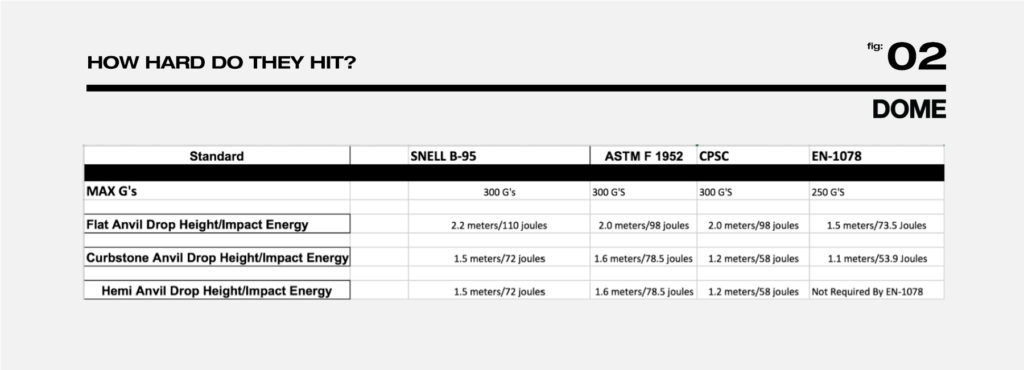

With different testing standards come different criteria for passing.

ASTM and SNELL (part of CSPC) test the highest impact forces (300G) while EN1078 requires the greatest coverage. All are testing linear drop impacts from fixed heights, but not rotational forces like independent test facilities like Virginia Tech’s STAR evaluation does.

While chin bars are not required to pass any test, if full-face helmets are tested, they must pass a deflection test for ASTM and SNELL.

By understanding these standards and what they mean, us mountain bikers can make informed decisions when choosing MTB helmets, making sure that safety is always a top priority.

Decoding Safety Standards

There are a couple of different mandatory standards for regions like US, EU and Australia. They ensure that minimum safety requirements for domestic markets are upheld.

Then there’s voluntary, often more demanding, independent third-party testing. The general criteria for all is maximal reduction of the initial impact force transfered onto the head – as measured in Gs.

They all have different test criteria for impact forces, coverage area, materials and angular impacts (hemi anvil tests).

CE EN 1078 (European Standard):

The EN1078 standard applies to helmets used by cyclists and skateboarders. It too focuses on a helmet’s ability to withstand impacts, the strength of its retention system, and its overall coverage. It uses various test anvils and simulates different impact scenarios.

Helmets must also withstand impacts using flat and kerbstone test anvils under guided free-fall conditions. And EN-1078 requires one of the lowest test lines (even compared to Snell and CPSC), which requires helmets to provide more coverage.

CPSC 1203 (US Consumer Product Safety Commission):

In the United States, CPSC certification is mandatory for all bike helmets. The CPSC standard for bike helmets is largely based on the ASTM F1447 standard.

It is known for being more demanding than the European EN 1078 standard. Helmets meeting CPSC standards undergo rigorous testing for impact resistance, strap strength, and coverage area.

It requires helmets to withstand higher energy impacts than the EN 1078 standard, including tests with flat and curbstone anvils. The CPSC standard also includes a hemi anvil test (side impacts), which is not required by EN 1078.

AS/NZS 2063:2020 (Australian/New Zealand Standard):

Updated in 2020, this Australian regulatory standard is considered in some aspects superior to the CPSC standard. It tests helmets for solid construction, ventilation, weight, and shock absorption.

There are higher performance thresholds for passing the AS/NZS 2063. This means that helmets need to demonstrate a greater level of impact absorption and resistance to qualify under this standard.

The AS/NZS 2063 standard may include additional criteria that are not part of the CPSC testing, such as specific design features, materials used, and other safety-related aspects that go beyond impact resistance.

AS/NZS 2063:2020 is also updated more regularly to reflect the latest research and advancements in helmet safety technology. This means that it may incorporate newer testing methods and safety criteria more rapidly than the CPSC standard.

ASTM F1952–10 (Downhill Standard):

While voluntary, the American Society for Testing and Materials standard is often incorporated into other mandatory standards, like CPSC. It applies to cycling and roller skating helmets, emphasizing the helmet’s ability to withstand impacts from different heights (resulting in varying impact forces) onto different areas.

It’s testing the highest impacts on curbstone and hemi anvils (lateral hits) of any standardized test. And while a chinbar is not required, full-face helmets undergo additional testing on their ability to deflect chin-bar hits.

Snell B-95

An update to the Snell B-90, the Snell B-95 standard is voluntary and known as one of the most demanding standardized helmet tests.

Helmets that meet this standard are subjected to impacts from greater heights to flat, and slightly lower test lines than the CPSC standard, requiring protection over a greater area of the helmet.

The few helmets that meet the SNELL standard are generally heavier and bulkier helmet designs – like half-shell and full-face MTB helmets.

The “best” helmet testing standard

Is the toughest helmet test always the best? Not really. Just because a helmet passes a high-impact test doesn’t mean it’s safer in real life. In mountain biking, impacts of 300G directly to your head (the threshold for lethality) are extremely rare.

If a test doesn’t match realistic crashes, its “toughest” label might be misleading. Outside of those strict lab scenarios, impacts are unlikely to be straight-on and more complex, meaning that rotational impact protection also comes into play.

Helmets passing the “toughest tests” often use denser (harder) foam. These helmets do great against curb-like shapes in penetration tests. But also transfer a lot of those impact forces onto the head.

But what about helmets with softer, less dense foam? They could be better at absorbing impacts on flat surfaces. So, which helmet is better? It depends on where you might hit your head – a square-edge rock, a root or flat dirt.

Another way to think about it is average speed. In downhill, a harder helmet may be more suitable for higher speeds, while for enduro and trail riding a softer EPS shell is the better decision.